Sucker Rod Makeup Procedure

A review of recommended procedures and tolerances based on API and sucker rod manufacturer information was conducted. Reference information is from API Recommended Practice, Norris, Weatherford, and Tenaris.

Throughout the design of the ARTL CD Sucker Rod tong, API Specification 11B, 27th Edition was used as a reference for sucker rod dimensions. API Recommended Practice 11VBR was used as a reference for care, handling, and makeup procedures. API RP 11VBR section 6.1 states:

“Both test data and theoretical calculations show that circumferential displacement beyond hand-tight makeup of coupling and pin provides an accurate and repeatable means with which to measure and define the preload stress in a sucker rod joint.”

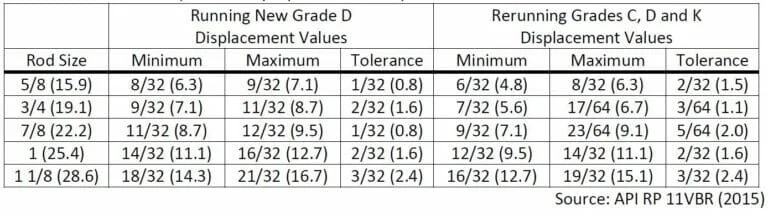

API RP 11VBR Table 4 gives Minimum and Maximum CD values for Grade C, D, and K sucker rods.

All dimensions in inches (followed by an equivalent in mm)

Note that sucker rods generally considered “High Strength” are not covered in API. High strength rods are made of materials that are proprietary to specific manufacturers but dimensionally conform to API. Each sucker rod manufacturer may define proper cd for their products. Where OEM cd values are not specified, the API values should be used.

Weatherford publishes cd values for their sucker rod that includes minimum and maximum values so that a makeup tolerance is provided. The values stated in the Weatherford recommended CD value tables match the tolerances shown by the thickness of the lines on the CD cards that are used in the field. Weatherford specifies that when the CD is checked, only the upper connection is compared to the card.

Tenaris publishes cd values for their sucker rod that includes minimum and maximum values so that a makeup tolerance is provided. The values stated in the Tenaris recommended CD value tables match the tolerances shown by the thickness of the lines on the CD cards that are used in the field.

Norris publishes CD values for their sucker rod that are considered to be the optimal makeup distance. The black and red cards that Norris supplies for sucker rods have lines on them that are approximately 0.020” wide and are to be considered the minimum acceptable makeup distance. Discussions with Norris Technical personnel have confirmed that the lines are considered the minimum acceptable and that exceeding the marks by up to 2/32” is acceptable.

The yellow cards that Norris supplies for PC Pump Drive rods have marks that are to be considered the minimum and maximum makeup distance. Optimal makeup distances for PC Pump Drive rods have not been published therefore the ARTL CD tong makeup distance must be set using the card as a reference.

The purpose of proper rod makeup is to create stress in the pin that exceeds the stress that will be induced in the pin by the cyclical motion of the rods as they move up and down in the well. The reason that circumferential displacement is preferred for makeup measurement over torque is that the stress is directly related to the distance the connection rotates and the angle of the threads. If the distance the connection moves beyond the shoulder is significantly different than what the rod manufacturers have specified, the stress in the pin will be less than or more than required which is the leading cause of premature failure. The second factor to consider for proper makeup is that the faces of the pin and the coupler need to be made up to the point of yield with no lubricant between them. The faces of the coupling and rod shoulder burnish to optimize the friction between them to ensure that they will not work their way loose.

When the rod is made up to a specified torque rather than distance, the distance it actually makes up will be affected by many factors including thread condition and cleanliness, temperature, and lubrication. The actual output torque of the tong will also vary due to tong condition and hydraulic fluid temperature and flow.

By controlling the distance that the tong moves rather than the hydraulic pressure to the tong, the effects of thread conditions, cleanliness, and lubrication will be eliminated when the tong is making single connections. When making up two connections at once, the two pins and the coupling must be in similar condition and equally cleaned and lubricated in order to ensure that the connections both makeup equally. It is imperative that proper rod connection preparation is done to ensure equal connection makeup when making up two connections at once.